It looks confusing. It is confusing. So let’s not start with an 1800cc flat six.

Modern bike engines come with a lot of technology – sometimes you need a dictionary just to translate the manual. But if you’re unsure how an engine works, it can be a bit daunting.

Blame him, it’s all his fault.

But the good news is modern engines still work on pretty much the same principles as they did when a German (might have known) called Nicholas Otto built the first one in 1876. And that’s already more than many pub experts know, so we’re off to a good start.

Motorcycle Engine Basics

The story starts with a bang inside a small, confined space. The bang isn’t an explosion; it’s a controlled burn of a mixture of petrol and air – the petrol got into the space by being squirted from an injector, and the air came from, er, the atmosphere. The bang/burn is also called combustion, as in ‘internal combustion engine.’ And the small, confined space is called a combustion chamber.

The really important bits – your basic engine

In the roof of the combustion chamber is a spark plug, which sparks, or ignites the fuel/air mixture and starts combustion. That bit is called ignition.

Gasses burning in small spaces expand, rapidly. The floor of the combustion chamber is actually the top of a piston, and luckily it slides down inside the walls of a cylinder – called a ‘cylinder’. Say what you like about engineers, but they’re logical.

The piston is connected to a rod, called a ‘connecting rod’ (see?) – shortened to con rod, or just rod. The rod is connected to a large axle-type thing, called a crank. As combustion pushes the piston and con rod down, they turn the crank.

Momentum in the crank (which is comparatively heavy) now swings the con rod and piston back up the cylinder again. This is useful because in doing so, it pushes all the burnt, exhausted gas out of the cylinder, through a pair of small valves that have just opened, and out into the, er, exhaust. A clever bit here – the timing of the valves opening and closing is controlled by a chain, running from the crank back up to a spindle (or camshaft) above the valves, and bashing them open precisely when needed.

Phew, so far so good. But the job is half done. We need to get more petrol and air inside the combustion chamber.

The complete four-stroke cycle. It’s hypnotic.

We now have piston at the top of its stroke again. But the crank still has momentum and is still turning, and it starts to pull the piston back down the cylinder – which is an ideal opportunity to open another pair of valves (controlled by another camshaft) and let the low pressure of the descending piston draw a fresh pulse of fuel/air mixture into the cylinder, a bit like drawing blood in a syringe.

Once again the piston reaches the bottom of its stroke, and the cylinder above it is full of swirling fuel/air mix. Still driven by crank momentum, the piston starts to rise again, for the second time, which compresses the mixture. When the piston reaches the top, the spark plug sparks again, igniting the mixture and pushing the piston back down the cylinder all over again.

So that’s a complete cycle of an internal combustion engine. If you’ve been counting, you’ll realise the piston actually went through two up strokes and two down strokes per cycle – that’s why it’s called a four-stroke engine (there are many other types of engine – two-strokes, wankels, diesels etc – but almost all modern bike engines are four-strokes).

The four strokes are often shortened into memorable verbs: in the order described above, it’d be bang, blow, suck, squeeze (but it’s more often ordered suck, squeeze, bang, blow, because it trips off the tongue better).

So now all we’ve got is a piston flying up and down, and a spinning crank. How does that make a bike go forwards?

As you’ll appreciate, the four-stroke cycle described above happens very, very quickly. Unbelievably quickly. When your bike is ticking over, the crank will be spinning at around 1200 revolutions per minute. That’s 600 sucks, 600 squeezes, 600 bangs and 600 blows every minute (because each one is half a crank revolution). And that’s per cylinder.

So the crank is spinning very quickly, but if you then just connected it with a chain to a back wheel, it would only have enough force to drive a motorbike very, very slowly, and it would be revving its nuts off to do it. If you imagine choosing first gear on a pushbike, then trying to pedal as you ride downhill; same thing.

What we need to do is somehow select a higher gear on our pushbike instead. We need a system of gears to slow down the rate at which the crank is spinning, and which then – because of a phenomenon called mechanical advantage – actually increases the strength of the force (also called torque) to the point where we can drive a motorbike forward at a decent rate but with the engine revving more sensibly. We want to swap high crank speed and low torque for low crank speed and high torque.

Ah, how about, a gearbox? So the crank has a cog, or gear, on the end of it, which turns a bunch of other gears of different sizes – and we can select which one we want, using a clever mechanism called a gear lever – before the drive appears, slower but much more forcefully, at an output gear – and from where we can hook a chain round it and drive the back wheel.

Now your bike has a running engine, and is moving. Hooray!

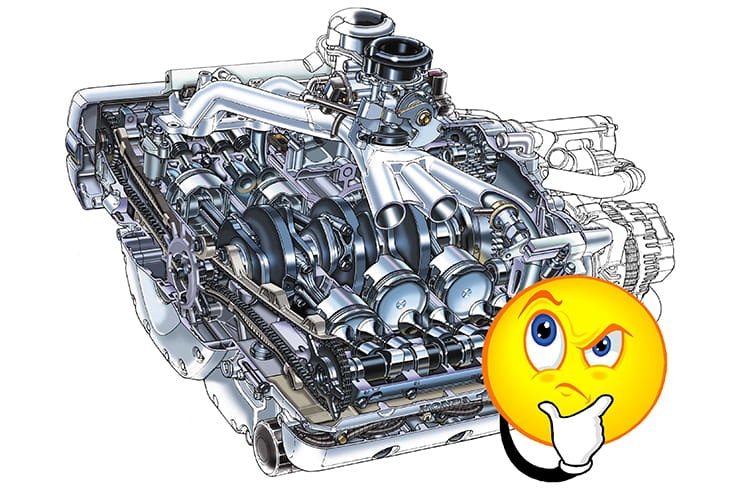

This is a drawing of a Triumph Trophy engine. You can see thre three pistons in a line, each on the end of a con rod and turning the crank beneath. You can also see the two inlet and exhaust camshafts across the top of the motor, actuating the valves. The big gear just behind the clutch basket is picking up drive from the crank and passes it into the gearbox – the cluster of gears. The drive output is the helical bevel gear at the bottom right. The Trophy has a shaft drive, and you can see its helical bevel gear picking up the gearbox output.

Of course, all the above only describes the process of one piston, rod and cylinder. You’ll know bikes can have one, two, three, four, not often five, but occasionally up to six cylinders. They can be arranged in weird and wonderful ways – next to each other (parallel twins, or inline threes, fours or sixes), in a V shape (V-twin or V-four), or facing each other (flat twin, flat four, even a flat six).

The number of cylinders and the way they’re arranged plays a huge role in determining not just the character of your engine (how it vibrates, and the way it delivers its power when you open the throttle) but also in the handling – and size – of your bike. Because of this, some configurations of cylinders suit specific types of riding – so single cylinders work well in dirt bikes but not so well in touring bikes. V-fours make good sportsbike engines, but lousy off-road engines.

Of course, this is only the most basic outlining of the way your bike engine works. Each engine has its own strengths and its own design quirks; it might be supercharged, or have variable valve technology, or a semi-automatic gearbox.

The beautiful thing about a four-stroke engine is when you gaze at a drawing of one, or an animation on YouTube, and suddenly understand for the first time the magical interconnection of piston, rod, crank, camshaft and valves. It’s a special moment, and one that can inspire a lifetime in engineering. It’s the same Eureka moment that once inspired the mighty Soichiro Honda – and, without doubt, every other engine designer, great or small.

VIDEO - How a motorcycle engine works

Motorcycle Engines - How it works?!

How does a motorcycle engine work; suck, squeeze, bang, blow.