Life after fossil fuel: Don’t write off combustion engines yet

By Ben Purvis

Motorcycle Journalist

22.02.2023

Fuel from fresh air? This prototype at ETH Zurich university already makes it

With the European Parliament’s formal approval of rules for a 100% cut in CO2 emissions from new cars sold from 2035 – aligning with the position already taken by the UK government and in California – the writing appears to be very firmly on the wall for the internal combustion engine. But as the scale of the challenge to manufacturer and charge affordable electric vehicles becomes ever clearer there’s a growing momentum behind the development of e-fuels that could harness existing infrastructure and even make current vehicles carbon-neutral.

The EU plans for zero carbon emissions don’t currently include motorcycles (although the UK government hopes to include them in its 2035 ban) and there are provisions for small-scale car makers building up to 10,000 vehicles per year, to hit more forgiving targets, but it’s clear that the focus is on electrification. However, there’s still potential for synthetic e-fuels to be allowed under the new rules, with a reassessment due in 2026, if manufacturers can prove they provide a genuine carbon-neutral alternative, and hydrogen-fuelled combustion engines would meet the ‘zero carbon emissions’ target. Indeed, a growing number of companies are recognising that the combustion engine could yet be a viable, green solution that doesn’t contribute to global warming.

Is synthetic fuel the future?

While some car makers, for instance VW, are committing to an all-electric future, motorcycle firms are increasingly looking to the solutions offered by synthetic e-fuels. MotoGP has committed to using 100% synthetic fuel – with no fossil element at all – by 2027, starting the shift in 2024 with a move to a 40% e-fuel mix. Ducati, while developing electric bikes, is also keen on carbon-neutral e-fuels. KTM has the same position despite a long history with electric-powered bikes, believing that electric power is a viable replacement for motorcycles up to 250cc but that larger, longer-range and higher-performance models are better served by e-fuelled combustion engines. BMW has invested in synthetic fuel company Prometheus.

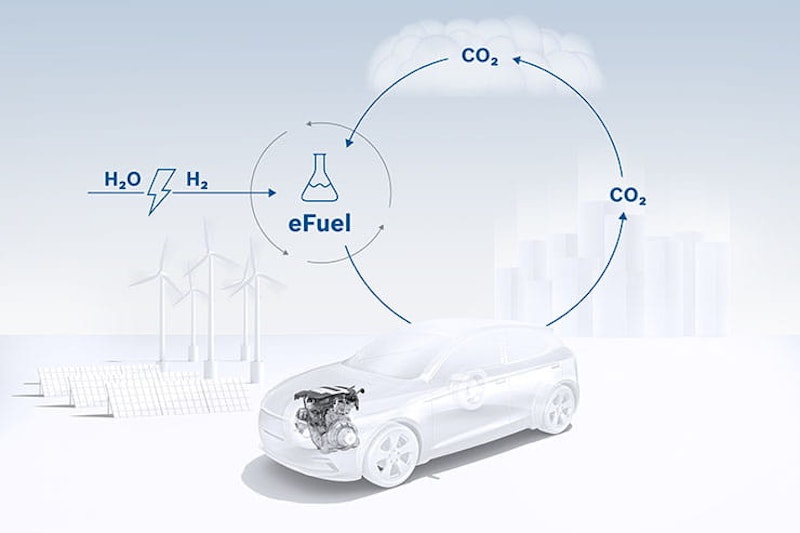

Although ethanol-based biofuels, made from crops, bio-waste or even algae, can achieve the carbon-neutral goal – i.e. they absorb as much CO2 while growing as they release when they burn – synthetic e-fuels made by chemically combining hydrogen and carbon to create a ‘drop-in’ replacement for petrol, are an even more tantalizing prospect.

Jamie Turner, Professor of Mechanical Engineering at King Abdullah University of Science and Technology, has decades of combustion engine design experience behind him. Having held positions in the past including Chief Engineer of Powertrain Research at Lotus and Gasoline Engine Research and Technology Manager at Jaguar Land Rover, he believes that combustion engines can be the solution, not the problem, when it comes to green transport.

Explaining e-fuels, he said: “It’s entirely possible to synthesize anything hydrocarbon-containing from CO2 and hydrogen. You just need the right catalysts. It’s actually a very commonly-used means to make things like methanol. A mixture of CO2 and hydrogen is called syngas – synthetic gas – it’s widely used in the petrochemical world.

“In the future, when we’ve got hydrogen – because we’re going to need that for the hydrogen economy, or whatever it might be – and where we’ve got a means of extracting CO2, then theoretically you can synthesize them together. In the first instance you’d probably make methanol. It’s easy to make via that process, as a liquid energy carrier. You can then take that and synthesise pure hydrocarbons, as methanol contains oxygen as well, or you can take the CO2 and hydrogen and put them into a much bigger process, called a Fischer-Tropsch process, and make jet fuel, diesel, gasoline, whatever you want. As long as all of your energy inputs are renewable, then you get a completely carbon neutral fuel as far as the atmosphere is concerned.”

Siemens, together with Porsche, have created an e-fuel plant in Chile

Of course, this all relies on being able to secure a supply of CO2 and hydrogen in way that doesn’t harm the environment, but Turner explains that it’s entirely possible.

“The bit that everyone thinks of as being really sci-fi is ‘where do you get the CO2 from?’” he said, “The cleanest way of doing it is to extract it from the atmosphere. There’s plenty up there, as we know. Those processes have actually been well understood for many years. It’s how you keep people alive on nuclear submarines: they have to extract the CO2 from the atmosphere. From the atmosphere it’s a bit more challenging because on submarines they let the level of CO2 rise to make it a bit easier, but people have been showing they can do this from atmospheric concentration CO2 for quite a long time. There’s a Swiss company called Climeworks that does it commercially already. So you’ve got CO2, extracted from the air, and hydrogen from electrolyzing water, all using renewable energy. Put those together and you can synthesize hydrocarbons.”

Pilot plants doing exactly this already exist. Siemens, together with Porsche, have created the Haru Oni e-fuel plant in Chile. Audi is developing e-fuels. In the UK, Zero Petroleum is promising the production of drop-in, carbon-neutral, synthetic fuel by 2027. Bosch has calculated that, over a lifetime, a hybrid car running on synthetic fuel could be cheaper to run than an equivalent all-electric car.

The benefit of these synthetic fuel plants is that they can be put in places where green energy is abundant. Turner explains: “You can site these plants anywhere in the world where there’s a lot of renewable energy – i.e. hot deserts. Normally, trying to get the energy out of a desert is difficult. You can’t do it as electricity because they’re usually too far away from where you want to consume the energy. Think about the Sahara or central Saudi Arabia, or most of Australia – any of the really hot deserts around the world – and instead of trying to get the energy out as electricity, you can synthesize a hydrocarbon and transport that.”

There’s a social benefit, too, as many of the places where there are deserts – the ideal places for solar synfuel plants to be set up – are poor. They have too much sunlight and heat, stifling the growth of crops, but that’s exactly what’s needed.

“You could help lift countries out of poverty,” said Turner, “ Because once you’ve built the plant, on an operating level they’re free. Sunshine is free. Air is free. Water might be slightly problematic, but if you have a coastline then water is basically free. What you make is something with a very high value-added aspect in the form of liquid fuel.”

The Haru Oni synthetic fuel pilot plant in Chile will be completed in March 2023. By the end of the decade production in Chile is expected to reach 550 million litres of e-fuel per year.

Inevitably, there are critics. Some will say that while synthetic fuels may be carbon neutral from a wider climate perspective, combustion engines burning them will still make local emissions. Others will point to the fact combustion engines will still produce NOx and particulate emissions, even if they’re carbon neutral. However, the benefits of e-fuels are hard to understate, and as Turner points out, it’s a technology that has to be developed anyway, saying: “This approach is the only practical way of decarbonizing aviation. People are looking at liquid hydrogen, and here might be a place for that, and they’re looking at electrifying short-haul aircraft, but you’re not going to fly to America on an electric plane anytime soon.”

Electric vehicles also come with their own problems, and ones that might be even harder to overcome.

Turner explains: “Ask yourself: what is the problem that we have? The problem is that the fuels that we use are fossil fuels and we are releasing CO2 into the atmosphere. The solution that everyone seems to think is the only thing that’s going to work is to completely change the energy distribution system to electricity, for which we have no infrastructure as far as transport is concerned. You have to develop new mining processes, new mines for lithium, for cobalt, all the other stuff – which is all in really short supply. You’re trying to change everything at once without looking at the real problem, which is CO2 in the atmosphere. If you take the e-fuels route you’re addressing that problem without trying to change everything else simultaneously. We have to do it anyway for aviation, so why not try to grow it to cover everything?”

A criticism of e-fuels that’s often raised is one of efficiency, and it’s true that combustion engines themselves, as well as the e-fuel manufacturing process, aren’t efficient. Turner has the numbers: “If you think about your primary resource as renewable energy, by the time you get the energy to the wheels of a vehicle via e-fuels using conventional technologies that we have available at the moment, it’s around 5% to 10% efficient. That’s bad. A big chunk of that is that engines aren’t very efficient – the run at about 20-22% efficient, so of all the energy you put in, a big chunk is lost. The synthesis process is quite good – electricity to methanol is about 50% efficient in terms of the energy contained in the methanol compared to the amount of energy that’s gone into the process, including the CO2 extraction. Actually, the worst thing is the electrolysis of water to get hydrogen – the water molecule is extremely stable and it takes a lot of energy to break it. About 80% of the total energy needed to make methanol using that route is to get the hydrogen, the other 20% is the overhead to make it easily storable as a liquid molecule. Basically, if you’re going to have a hydrogen economy, you need a lot of energy, and making methanol on top of that is only slightly more energy.”

However, the ability to site e-fuel plants in inhospitable parts of the world once again helps. Turner says that solar panels covering less than 1% of the Sahara Desert would provide energy to synthesise e-fuel enough fuel to cover all Europe’s transport needs. “If you look at the amount of solar energy that hits the world on a daily basis,” said Turner, “We have over 1800 times as much energy hitting the world as we use for everything.”

“You can’t shoot down e-fuels on the basis of efficiency because we have no shortage of energy, and what’s more it gives us the flexibility to go places to get it that aren’t practical simply for electricity generation.”

Kawasaki’s prototype hydrogen-fuelled engine is based on the H2’s supercharged four-cylinder

Is hydrogen a better fuel than petrol?

One of the key elements of e-fuel is hydrogen, and hydrogen itself is also a potential lifeline for the internal combustion engine.

We’ve already seen big players including Yamaha and Kawasaki developing hydrogen-fuelled combustion engines. The former recently created a hydrogen-powered V8 for Toyota (always a close Yamaha partner) and Kawasaki has been working on a hydrogen-fuelled version of its supercharged H2 four-cylinder engine. There are also smaller efforts out there, including Australia’s Salt Motorcycles which is working on a 1200cc, hydrogen-fuelled V8 bike (Salt Motorcycles’ owner, Brendan James, also runs hydrogen production firm LINE Hydrogen).

While hydrogen isn’t a drop-in replacement for petrol, and to be used in combustion engines needs them to be developed specifically for that purpose, the combustion engine is still a tempting way to turn hydrogen into motion.

“Hydrogen combustion engines won’t be as efficient as fuel cells,” said Turner, “But they have serious advantages in other respects. One is that they’re dirt cheap to make. Engines are really cheap in comparison to any of the other technologies – batteries or fuel cells – and the other advantage is that a hydrogen combustion engine can happily consume hydrogen with quite a lot of trace molecules, like carbon monoxide, that will poison a fuel cell. So having hydrogen engines to pull the hydrogen infrastructure forwards as you make the hydrogen cleaner is quite a neat flexibility.”

Hydrogen-powered Kawasaki carries the fuel in replaceable cartridges in the panniers to solve refuelling problems

Although the message from politicians in recent years has been firmly in favour of battery-electric vehicles rather than e-fuels, Turner says that’s starting to shift: “I’m beginning to see the signs of some realism. The penny is starting to drop that if electrification doesn’t work, we will have flushed away the European heavy industry of making cars. Even if we go to electrification, the number of people employed is much, much lower, and we’ll be buying all the batteries from China.”

There’s also the risk of a ‘Havana Effect’ – where people can’t afford the latest, battery-powered vehicles and are instead left trying to keep old, combustion-powered ones on the road. It’s named after the phenomenon in Cuba where, after Castro’s Communist revolution, it became essentially impossible to import cars from the West, meaning that for decades the streets have been filled with cars from the 1940s and 1950s. E-fuels instantly solve that problem by allowing existing vehicles, however old, be carbon-neutral when it comes to emissions.

“E-fuels are blendable with what we have at the moment,” explained Turner, “You can start to decarbonize all the vehicles as soon as you put e-fuel into the distribution system. The problem with the ‘legacy fleet’ is that it’s totally left by battery vehicles, and if we don’t decarbonize the fuel they run on, we’ll always be emitting fossil CO2 if that’s where the fuel comes from.”